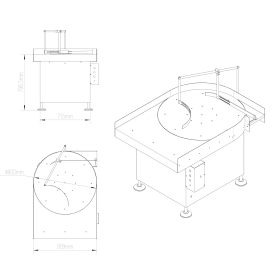

1.JGP series Rotary Turntables are manufactured to increase the efficiency of any production line. Our Loading or unscrambling Turntables transfer single filed bottles onto a conveyor, enabling operators to maximize production capacity.

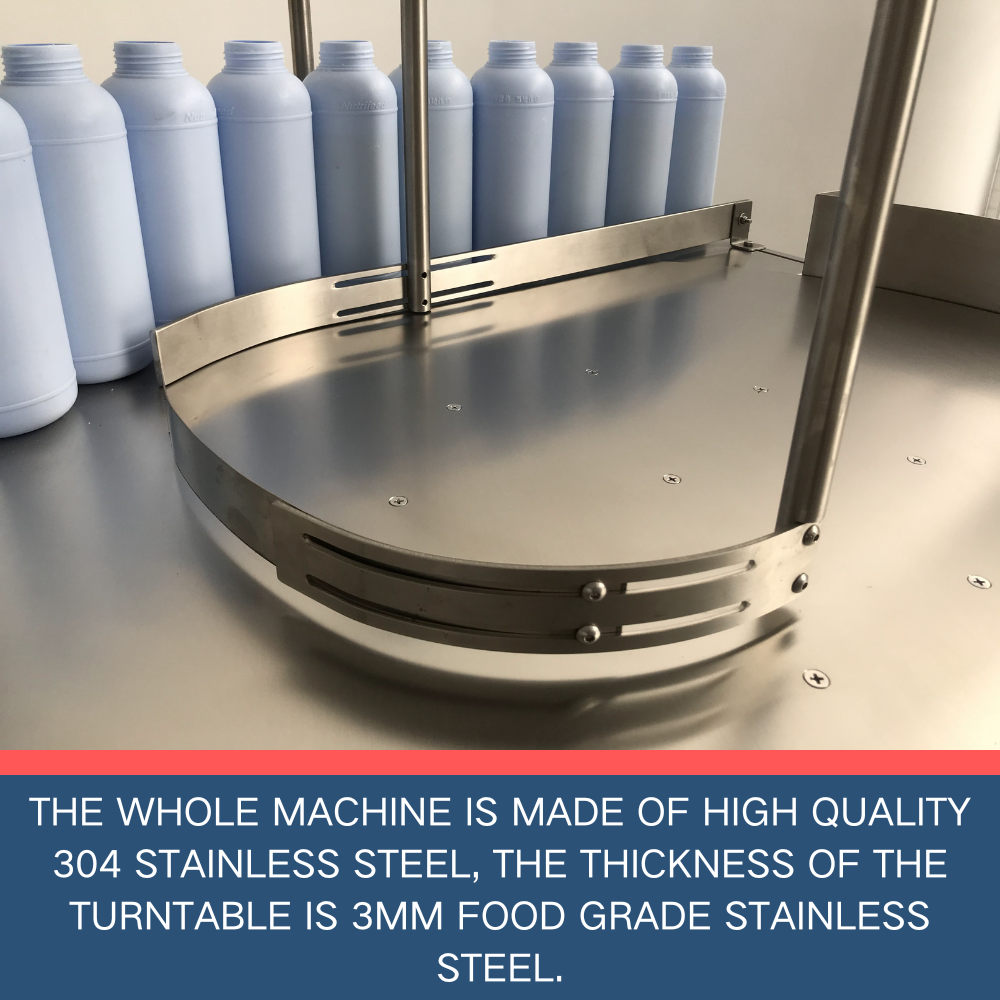

2.Our standard construction is comprised of a heavy duty 304 stainless steel frame.

3.Optional models are available for sanitary, hazardous, flammable and corrosive production lines.

4.JGP series Rotary Turntables are used in the production of cosmetics, food and beverages, cleaning and specialty chemicals, pharmaceuticals, personal care and more.

|

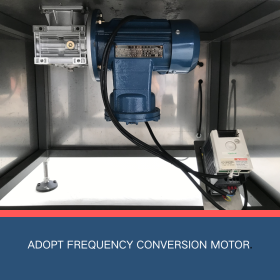

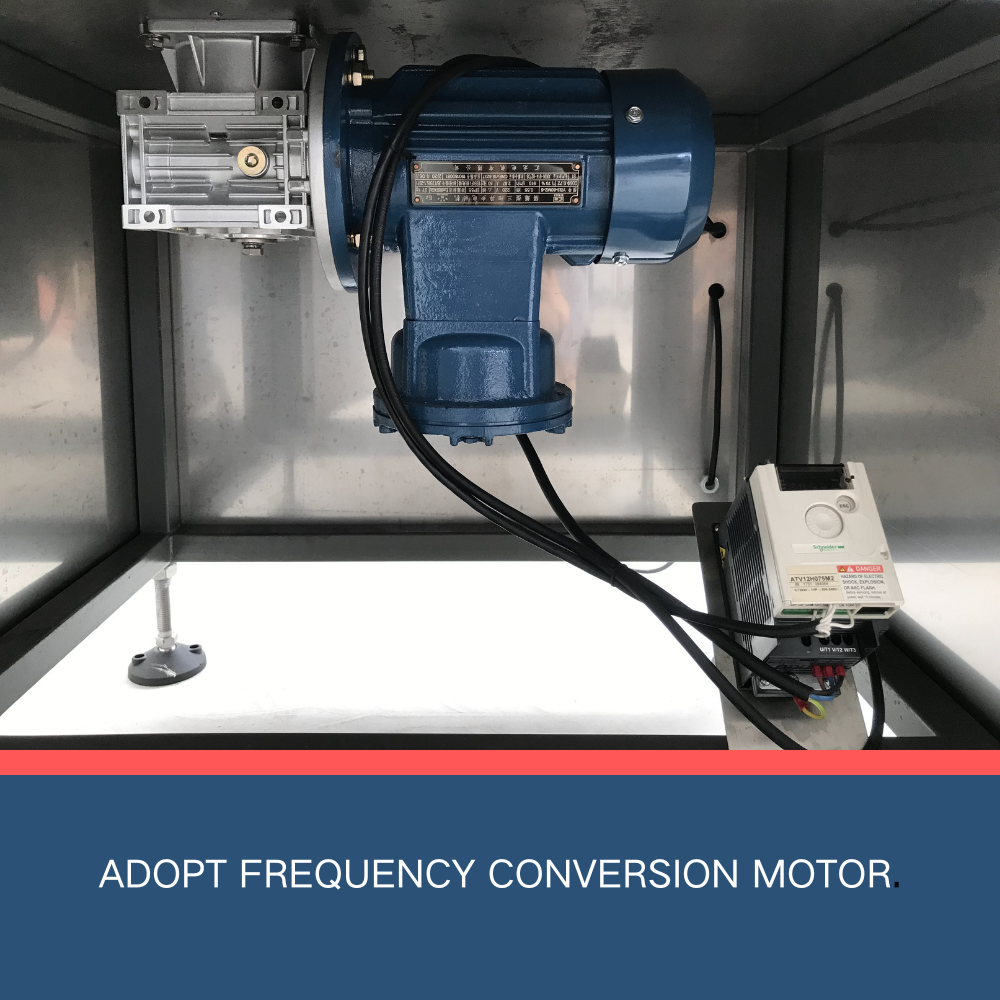

Adopt frequency conversion motor.

|

|

Adopt French Schneider brand low-voltage electrical buttons |

|

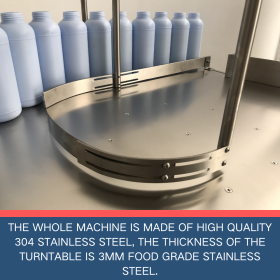

The whole machine is made of high quality 304 stainless steel, the thickness of the turntable is 3mm food grade stainless steel. |

|

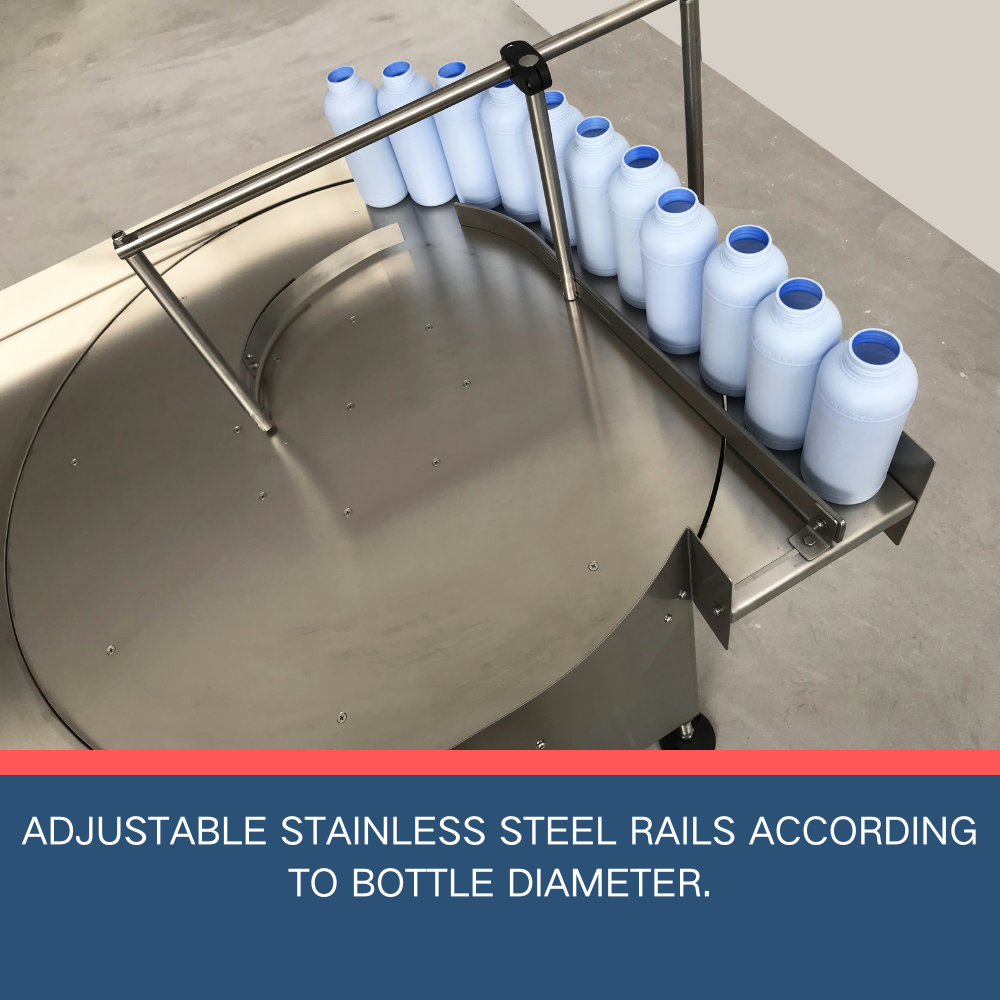

Adjustable stainless steel rails according to bottle diameter. |

|

The bottom of the stainless steel disc is supported by aviation aluminum alloy, which makes the load stronger. |

Auto Bottle Packer

Auto Bottle Packer