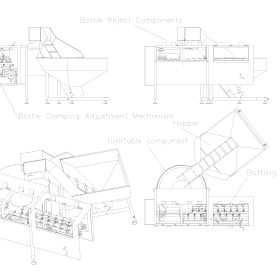

Equipment introduction:

JLP-200F Automatic Bottle Unscrambler is making up of bottle elevator ,round plate,bottle rejector, bottle-arranging and the electrical cabinet . Put disordered bottles to the bottle elevator, through round plate, conveying belts, bottle arranging parts , then bottles can stand on the belts. This machine is characterized by the compact structure, simple operation principle, mature technique and stable movement.

Bottles poured into the rotator plate, with belts conveying to the unscrambling device; bottle standing orderly on the conveyor belts. This machine is of high speed, round and flat bottle both applicable. No need to change any part when changing the bottle specification. It is with auto rejecter and no-bottle alarm function.

Equipment details and features:

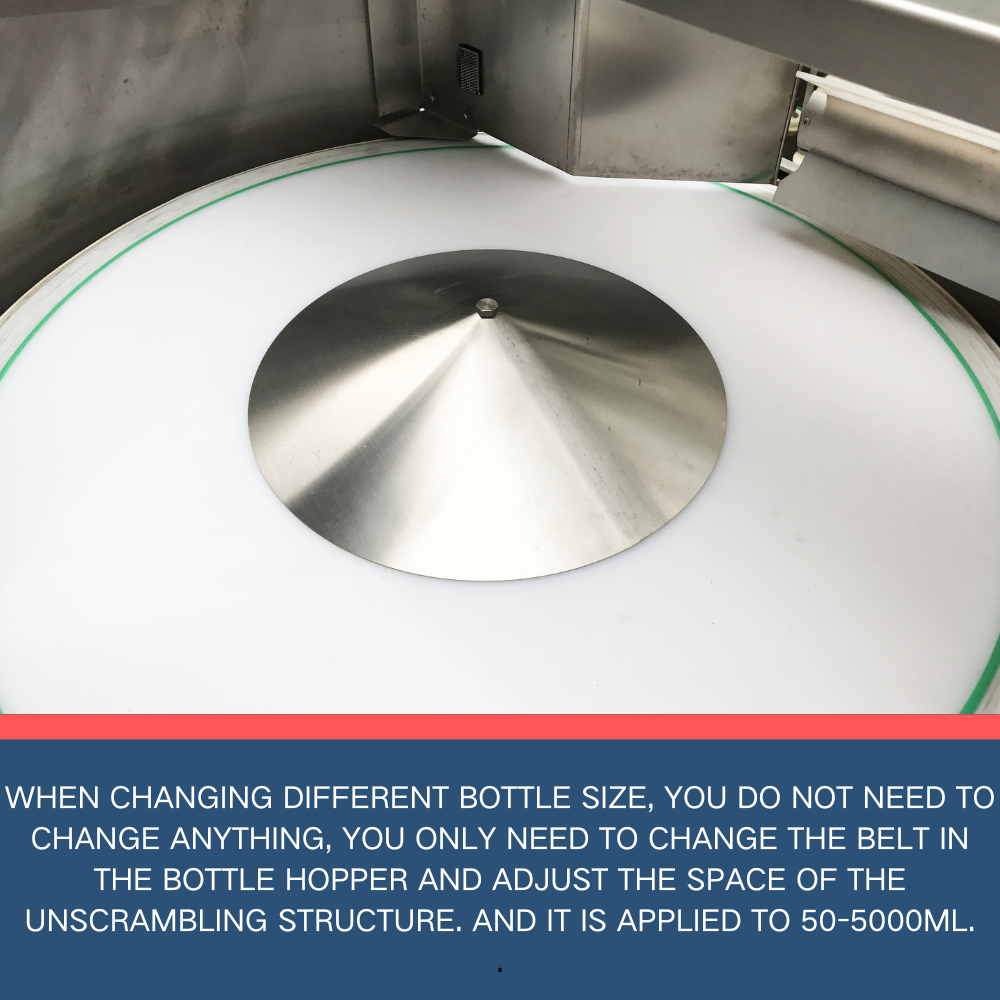

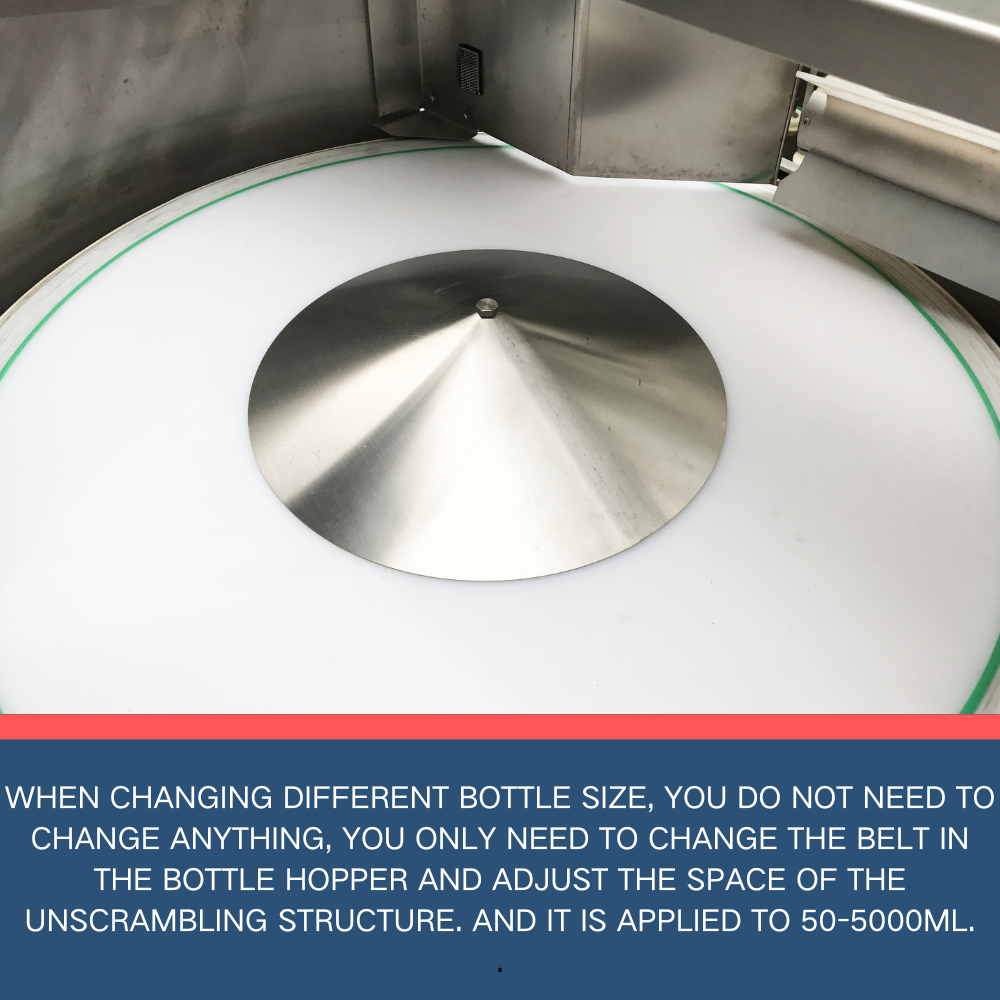

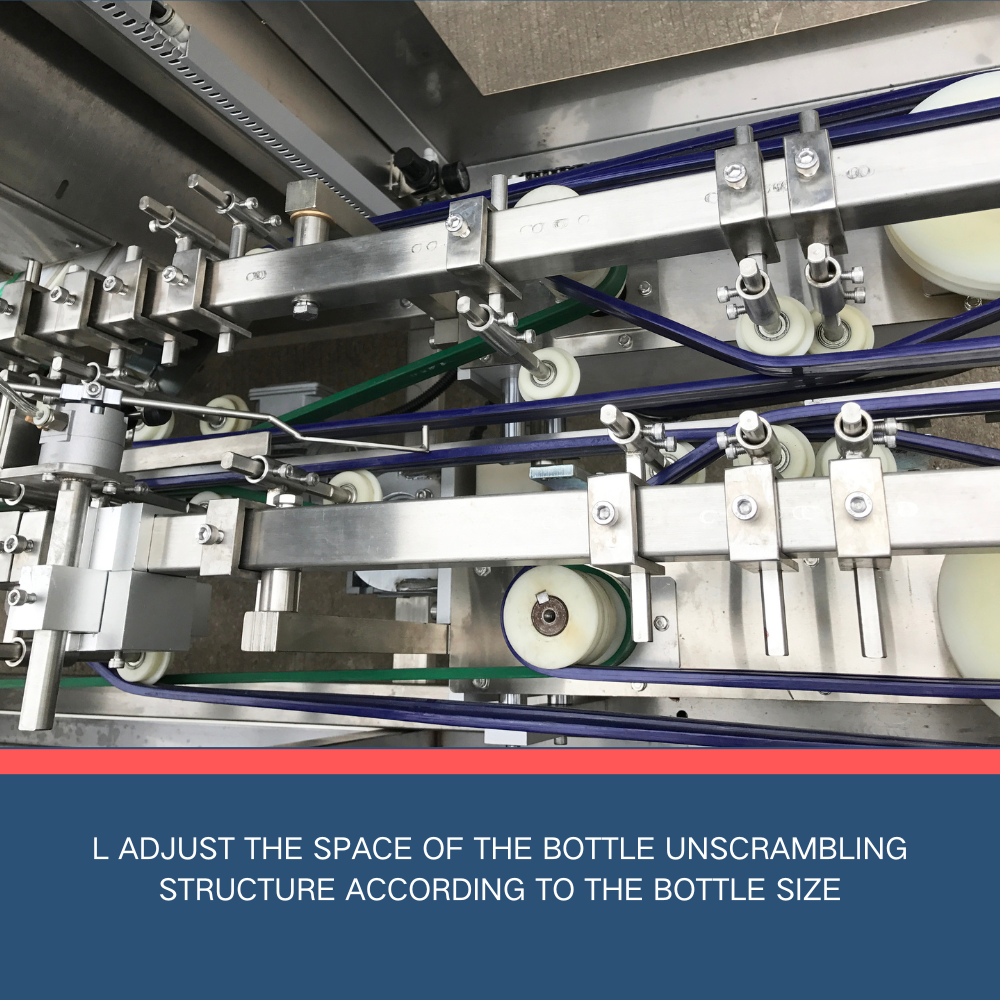

When changing different bottle size, you do not need to change anything, you only need to change the belt in the bottle hopper and adjust the space of the unscrambling structure. And it is applied to 50-5000ml.

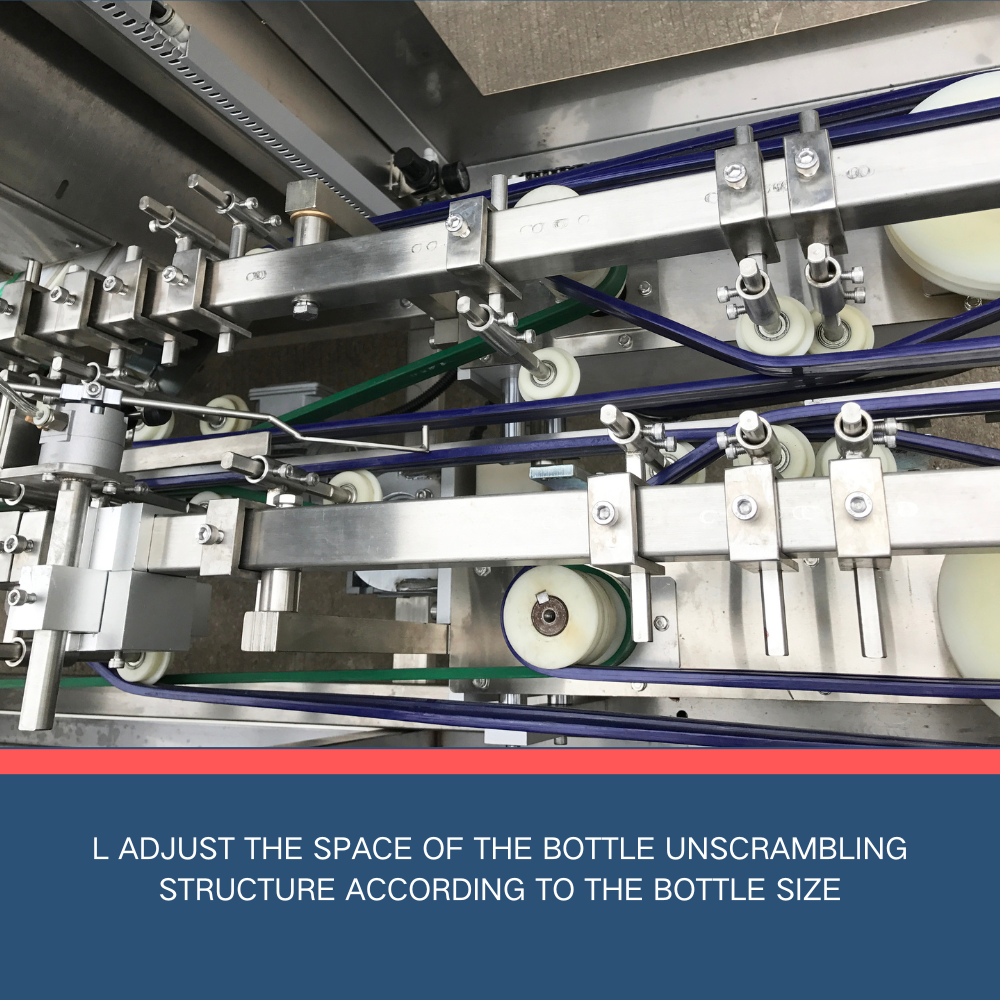

- Adjust the space of the bottle unscrambling structure according to the bottle size

- The electrical components are all imported which ensures its long service time and stability.

- The whole machine is covered with organic glass, you can open all the cover for easy adjustment.

- All the organic glass cover is installed with the sensor. The machine only can start when all the organic glass cover are closed,and will stop when any of the door is open.

- The connecting belt in the machine are shaped in one time, not easy to broken.

- Automatic bottle elevating function, you only need to put the bottles in the bottle elevator, a sensor is installed in the rotary plate, it will automatically elevates the bottles when there is not enough bottle, it will start when the bottles are enough consequently.

- Coordination sensor, it will stop bottle unscrambling when there is jam of the other sections of the filling line, it will start again when the jam is cleared. It will have the perfect linkage with the other sections of the filling line.

What is a Bottle Unscrambler and How Does It Work?

Un bottle unscrambler is a crucial machine in bottling operations, designed to automatically feed bottles onto production lines at high speeds. This automation eliminates the need for expensive and inefficient manual labor. While various designs exist, they all serve the same core purpose. This article focuses on the operational principles for plastic and other non-fragile containers. For delicate materials like glass, metal, or ceramic, which can be damaged by impact, different machinery such as depalletizers are used for automatic feeding.

How Bottle Unscramblers Function?

Bottle unscramblers start by receiving containers in random orientations from a large hopper, which can hold thousands of bottles. From the hopper, bottles are moved through different stages of the machine and sorted until they stand upright on a conveyor. This conveyor then transports them to subsequent stages of the filling line, such as a bottle filler, capping machine, o labeler.

As an example, let's look at the operation of our JLP-200F bottle unscrambler model. This machine uses an inclined conveyor to transfer containers from the hopper to a rotating bowl. On the rotating bowl, the bottles are organized so they are either "neck leading" o "neck trailing."

Próximo, a hook allows bottles that are "neck trailing" to pass through, while turning bottles that are "neck leading." This ensures all containers end up lying down with the neck following.

Finalmente, a designed speed difference between two sets of belts, combined with mechanical design, allows the containers to stand upright. To better understand this process, reviewing accompanying videos is recommended.

Key Considerations for Bottle Unscramblers

This is a basic overview; the thousands of available bottle designs mean each container requires analysis for proper unscrambler operation. Several factors need to be considered:

1. Required Speed

As the initial machine in a bottling line, el bottle unscrambler must operate at a speed that allows it to keep pace with other filling equipment, even if there's a stoppage.

2. Container Size

Container size is vital for recommending the appropriate machine. For instance, a 32-inch bowl machine can handle over 200 two-ounce bottles per minute, but only 10-15 gallons per minute. Similarly, a 25-cubic-foot hopper can hold thousands of two-ounce bottles, enabling long periods of unattended operation. Sin embargo, it will only accommodate a few dozen gallons, requiring more frequent refilling.

3. Design Features

Every container design feature can pose a challenge during the unscrambling process. Issues might include bottles that are too soft, ridges that cause damage, dimensions that make orientation difficult (p.ej., similar bottle diameter and height), or guides on the bottle that snag the hook.

4. Installation Location

Many production lines initially operate without a bottle unscrambler. When considering adding one, finding suitable space on a liquid filling line can be challenging, as these machines are often large. They are typically positioned before the liquid filler o powder filling machine. Some customers also install the unscrambler before the labeling machine if labeling prior to filling is convenient.

5. Material

Container material presents various challenges, including the potential for marking, scratching, fragility, or other quality issues. For example, PET bottles may require special handling during sorting to prevent scratches on a PET bottle unscrambler.

6. Cleaning Containers

While we offer an air rinsing option on our unscramblers, it's important to note that the cleaning provided by ionized air or ionized air rinsing systems is minimal. For containers requiring thorough cleaning, a dedicated bottle rinser is recommended.

Secondary Orienting

Some containers require secondary orienting to ensure they are in the correct position before entering liquid filling or packaging equipment. This additional orientation is necessary when bottles emerge from the unscrambler in multiple positions. A motor oil quart with an off-center neck is a good example; a typical unscrambler might feed these non-symmetrical containers either neck leading or neck trailing. To fully automate the packaging line, secondary orientation is then required.

Each container presents unique challenges, leading to various types of secondary orienters. The most common include:

Container Orienting with Belts by the Neck: This inline system holds the container by its neck. It then uses either the container's shape with mechanical guides, or servo/stepper motors on each belt, combined with sensors or cameras, to detect incorrect positioning. A signal is sent to adjust the differential speed, orienting the container by the neck. You can see this process in this

Container Orienting with Side Guides (Servo-Driven): This machine uses sensors and cameras to identify incorrectly positioned containers and then mechanically rotates the container 180 degrees at very high speeds using servo motors.

Container Orienting on Rotary Machines: These machines utilize infeed screws and starwheels to guide containers onto pedestals. The pedestals rotate the containers based on their position, as determined by sensors or cameras. This method is ideal for handling unstable containers or when high speeds are required. Sin embargo, the main drawbacks are the cost of the machine and the price of change parts.

The packaging machinery industry offers many designs for feeding bottles into packaging machines. Our chosen design prioritizes flexibilidad, allowing it to handle a wide range of containers with minimal change parts. This efficient design makes our automatic bottle unscrambler more cost-effective and accessible to our customers. For speeds exceeding 500 bottles per minute, continuous rotary unscramblers are available, though their main disadvantages are higher cost, greater space requirements, and expensive change parts.